What Adjustments Have the Greatest Effect on the Time to Count 20 Bolts?

For the by twoscore years, when the oil and gas industry idea of bolt lubricant, it focused on disassembly — i.eastward. the breakout torque seen at the commodities head or at the nut of the fastener.

What went unexplored until recently was how lubricant affects the Nut Factor on a fastener, which then affects tightening torque, and therefore effects the bolt tension.

But that'southward just the starting time.

Through years of enquiry and first-manus experience, we have found that many lube manufacturers don't know how their lube performs in the field. They often don't sympathize the divergence between friction coefficient and Nut Factor.

That's a problem, because y'all attain the applied torque on your fastener through understanding your Nut Factor. If those numbers are off, and so your terminal torque values will be incorrect no thing what your torque reading might be.

In this article, we'll assistance you avoid those problems by explaining:

- What is Bolt Lubricant?

- A Cursory History of Bolt Lubricant

- Why You Use Bolt Lubricant

- Galling

- An Introduction to K-Gene

- How Much Commodities Lubricant to Use

- How to Apply Bolt Lubricant

- Commodities Lubricant Torque Chart

What is Bolt Lubricant?

Any lubricant is designed to reduce friction and wear between ii surfaces in contact. Bolt lubricant is a little more than complicated than that.

In the by, bolt lubricant has been associated with disassembly, and therefore many in the oil and gas will refer to it equally "anti-seize." Simply commodities lubrication is also crucially important for assembling flanges properly.

Using proper bolt lubrication practices will allow assemblers to achieve the ideal torque with a low degree of commodities scatter (which we define as differences among torque levels on dissimilar bolts property together the same flange).

Proper commodities lubrication means:

- Consistent frictional backdrop: In guild to make up one's mind your torque value, you have to sympathise, and solve for your K-factor. K-factor, which tin also be called "nut factor," is an experimental number. It is non acceptable to use a friction coefficient or a friction factor adding. In fact, PCC-i just took out Appendix J which is the Friction Factor Adding.

- Adequately Lubricated Fasteners: There are very few situations in bolting together flange joints where you lot can over-lubricate a stud. You should e'er exist able to run into a dewdrop of lube "squish" out the bottom of the nut. This means that y'all have put adequate lubricant on all surfaces that need it.

- Lower Breakout Torques (no galling): Galling is a form of wear acquired by adhesion between sliding surfaces. When a cloth galls, some of information technology is pulled with the contacting surface, especially if there'southward large corporeality of force compressing on the surfaces together. Sure lubricants, such as nickel lubricants, can actually cause galling.

- Physical and chemical stability: In the past, the petrochemical industry used copper-based lubes in the past every bit their standard. However, they discovered these types of lubes don't play well with hydrogen and can lead to hydrogen embrittlement, which can corrode, crevice, or otherwise deteriorate surfaces. Then the industry moved to nickel-based lube, but in that location was another problem: Information technology causes galling to accelerate. Now the manufacture has moved to moly lube. Moly lube is technically a mineral, helps prevent galling, and is good for well-nigh environments.

- Ease of awarding: The ability to apply lubrication is a different bailiwick than adequate lubrication. Why? If the lube can't come out of the can because it's a solid at lower temperatures, an assembler won't be able to apply it adequately.

A Brief History of Thread Lubricant

Equally we mentioned earlier, commodities lubricants were initially idea of as anti-seize. Companies like Jet-Lube have produced anti-seize thread lubricants for seventy+ years for the upstream industry. To this day, the use of copper-based lubricant Kopr-Kote(TM) is the standard lubrication in the field.

Therefore it doesn't seem unreasonable that when the residuum of the petrochemical and power industry started to focus on anti-seize products for a bolted joint, they turned to those copper-based lubricants. But they discovered copper lube was non good for all systems because it doesn't play well with hydrogen.

Instead, the industry then turned to nickel-based lubricants. This type of lube was considered practiced because of its high-temperature rating, up to 2500 degrees Fahrenheit. (But note: That is the melting signal of nickel and non a good method for determining what a good lube looks like.)

Recently the petrochemical manufacture has moved to molybdenum disulfide, which is also called "moly" lube. Currently this is the best type of lube for assembling bolted joints, because it does not cause hydrogen embrittlement if mixed with the correct chemicals.

(Notation: Pure moly lubricants are non recommended around hydrogen. Check with the manufacturer.)

Why Use Bolt Lubricant?

There are ii main reasons why lubricated fasteners are better than non-lubricated fasteners.

ane. Galling

Galling is one of the most frustrating things nosotros meet in the field as assemblers.

The true definition of galling comes from ASTM G40, and information technology says galling is course of surface damage arising between sliding solids distinguished by microscopic, normally localized roughening and creation of protrusions, i.e. lumps, in a higher place the original surface.

Then what does that mean to the assembler?

It ways we're grinding steel on steel to stretch steel. That's what we're doing when nosotros use torque. So if we want to get rid of galling, one of the best ways to is to properly lubricate.

The other role of preventing galling is in what blazon of lubricant y'all are using. That'southward why you've seen an increase of molybdenum disulfide lubricants (a.k.a "moly" lubricants) in the industry.

2. Achieving Proper Bolt Torque: An Introduction to K-Factor

Hither we need to hash out:

- Non-Lubricated Bolts (a.yard.a. Dry Torque)

- Partially Lubricated Bolts

- Properly Lubricated Bolts

Merely earlier we talk well-nigh these items, or become to our torque nautical chart, it is imperative you empathize the working definition of One thousand-Factor (or "Nut Cistron"). ASME PCC-1 states:

"K is an experimentally determined, dimensionless abiding related to the coefficient of friction."

Translation: You need to take experimental information on what Nut Factor you take. DO Non rely on just the coefficient of friction numbers. Some manufacturers will say they are the aforementioned, or they volition non take washed Nut Factor testing at all. Please practice your homework on this.

"Published tables of experimental nut factors are available from a number of sources; nonetheless, care must be taken to ensure that the factors are applicable to the application existence considered."

Translation: Yous need to make sure whatsoever previous testing was washed on applications that represent what you are working with. For instance, we once saw a company do a test on 1/4 inch bolts. The trouble: The average size bolt in the petrochemcial manufacture is three/4 inch. And then those tests weren't especially helpful.

"It should also be noted that recent inquiry has shown there to be nut factor dependence on bolt cloth, bolt diameter, and assembly temperature. These factors can be pregnant and should not be ignored when selecting the nut factor or anti-seize chemical compound. The user is advised either to seek test results conducted on similar commodities and anti-seize specifications or to conduct nut factortrials (size and textile) with their ain atmospheric condition."

Translation: Become your hands on their enquiry! It's the only mode you tin verify that they have done their homework.

(Beyond ASME PCC-1: Learn what today'due south bolting professionals need to know.)

Non-Lubricated Bolt Nut Factor:

Information technology's non possible to determine an authentic Nut Gene for dry threads. Unfortunately, when you don't have lubricant, at that place are many other substances that may human action as lubes on your fastener that you might not be able to come across.

One of them is the oil used on them during manufacturing. For example, nosotros accept seen a stud where the oil has been "baked off" using an oven have a Nut Gene of near .26, while a stud that still has oil residue is nearly a .20. (It's worth noting that particles of solids all the same on the stud that will also affect your Nut Factor).

That is a big discrepancy.

Hex Engineering recommends that you do not endeavour to solve this problem unless you lot take the proper equipment and empathize the "Turn of the Nut Method."

Partially Lubricated Bolt Nut Cistron:

Let's say y'all've done your homework and empathise the nut gene for your lube. If that lubricant isn't applied generously/properly, the dry parts of the fastener will increase your Nut Factor and consequence in different bolt loads on each of your fasteners.

So you might be using a calibrated torque wrench, and take a known Nut Factor, but if your lube isn't applied properly, your torque value (bolt tension) will have changed.

(Acquire more than well-nigh how to properly use clicker wrenches.)

Properly Lubricated Commodities Nut Factor:

When testing your Nut Gene, you put information technology in the best and almost repeatable condition, so you replicate those weather in the field. By properly lubricating fasteners, you achieve the right ft-lbs, clamping force/preload, and gasket stress.

How Much Lubricant Should You Use?

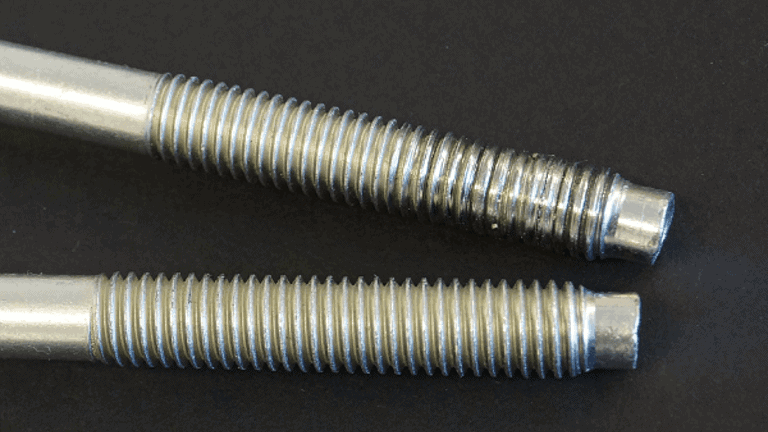

Proper lubrication means that you've put lubricant on every thread so that the valley of the stud is total.

Detect how we lubricate enough so that when you paw rotate the nut downward, at that place's a little bead of lube that squishes out. This ways that we've put lubricant on all the parts that will experience friction when we apply torque.

How to Apply Bolt Lubricant

When you use lubricant, be certain that all valleys of the stud bolt threads are filled.

Once the nut is hand tightened, you should see a bead of lubricant extruding from beneath the nut. This indicates that the lubrication has been applied to all working surfaces.

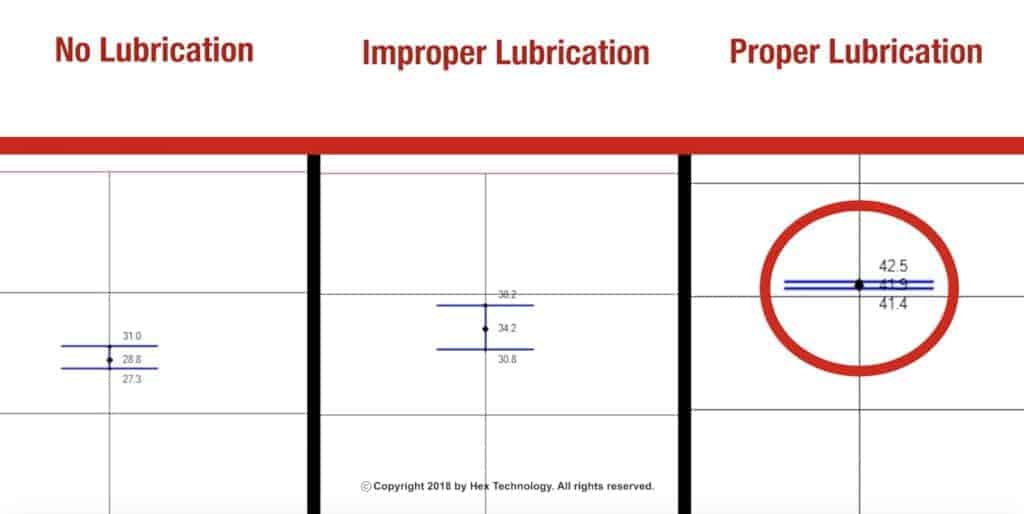

In this screenshot from the video above, notice how the varying levels of bolt lubrication atomic number 82 to meliorate results:

No lubrication: You lot will see that, without lubricant, bolt stress is lower than our target commodities stress of forty Ksi. In the video above, our test on unlubricated studs examination averages 28.8 Ksi, with the low corporeality being 27.three and a high of 31.

Partial lubrication: Inconsistent or merely partially lubricating the studs will consequence in unfavorable bolt stress. In the second examination, by using lubricant the boilerplate bolt stress increased past v.4 Ksi, only still came up brusque of our target of 40 Ksi. Bolts that are non lubricated in the aforementioned way will take a greater variation in the bolt load.

Proper lubrication: Properly lubricated studs volition outcome in a tight bolt load at our desired stress target. Notice how bolt load has increased, and we're now achieving bolt loads much closer to the target bolt load of forty Ksi. And find how the variation among the bolt loads (a.1000.a. bolt scatter) has drastically reduced when all working surfaces are properly lubricated.

Bolt Lubricant Torque Chart

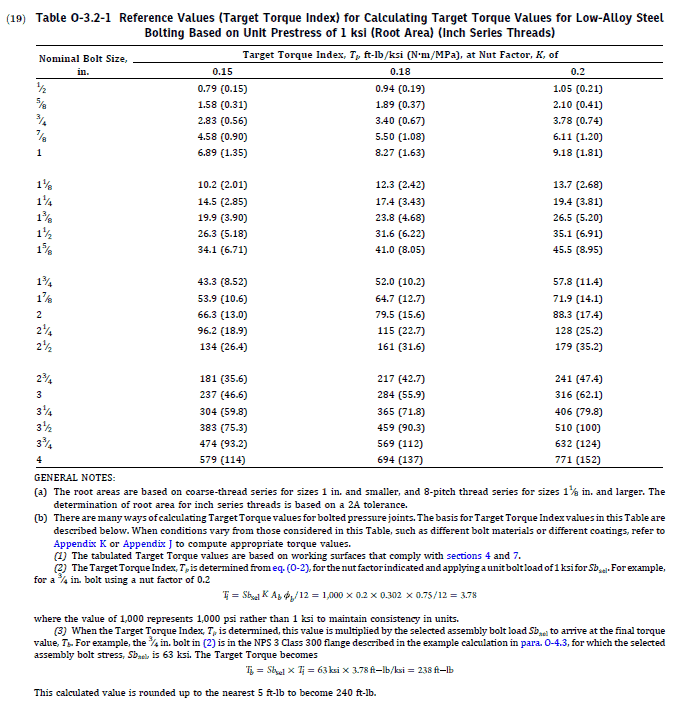

PCC-1 published Table O-3.2-1 "Reference Values (Target Torque Index) for Calculating Target Torque Values for Low-Blend Bolting Based on Unit Prestress of 1 ksi (root surface area) (Inch Serial Threads).

This was done to ensure you tin can use it to make up one's mind and arrange to stainless steel fasteners that have a lower tensile strength.

Notation: The in a higher place chart shows you how to determine your torque IF y'all have either a 0.xv, 0.18, OR 0.ii Nut Factor. But once more you demand to experiment with what lube you have and confirm the Nut Factor is in order to make a torque specification.

Related Articles:

How to Foreclose Galling (and "Faux" Galling)

A Guide to K-Cistron

Larn more nigh the technical aspects of bolted flange joint assembly.

Bring together Industry Leaders!

Subscribe to Hex Technology today and we'll requite you $700 in bolting courses, Gratuitous. Your path to a safer, more reliable, more profitable site starts here.

Source: https://www.hextechnology.com/articles/bolt-lubricant-torque/

Post a Comment for "What Adjustments Have the Greatest Effect on the Time to Count 20 Bolts?"